While districts such as Barnala and Sangrur have seen 100 per cent conversion to the new technology, of about 270 kilns in Ludhiana, about 100-125 are still to convert.

After grappling for decades with its 2,800-odd polluting brick kilns, Punjab has got most of them to switch to a new technology, thereby cutting emissions by an estimated 70 per cent.

After a few initial hiccups, officials of the state pollution control board say they have been able to convince the owners of at least 1,800 kilns to opt for the newer ‘induced draft’ kilns with zigzag brick settings.

In the new kilns, the bricks to be baked are arranged in a zigzag pattern, allowing hot air to cover a longer path, unlike in traditional kilns, where the bricks are arranged in straight lines. As the air takes this zigzag path, it improves the heat transfer to the bricks, thus making the operation more efficient.

Besides, the mixing of air and fuel in the new kilns allows for complete combustion, thus reducing coal consumption by about 20 per cent. The new kilns also use fans to regulate air.

Officials say kilns in Punjab produce around 15-20 billion bricks per annum, making up about 8 per cent of the total production in the country, and employ about 5 lakh workers.

Following orders from the National Green Tribunal (NGT) and guidelines from the Central Pollution Control Board (CPCB), the Punjab government had directed traditional kilns to stop operating by March 31. But less than 500 converted, forcing the government to extend the deadline to September 30. Since then, officials say, over 1,200 kilns have converted.

Recently, the Punjab and Haryana High Court refused to grant any relief to kiln owners who had appealed against the government’s orders.

“Punjab’s air turns toxic during this time of the year due to paddy stubble burning. The traditional kilns have been adding to the problem. But now, we are not only trying our best to stop paddy stubble burning but also preventing polluting kilns from functioning. The Ambient Air Quality (AQI) is less than 200 this time,” said an official of the state pollution board.

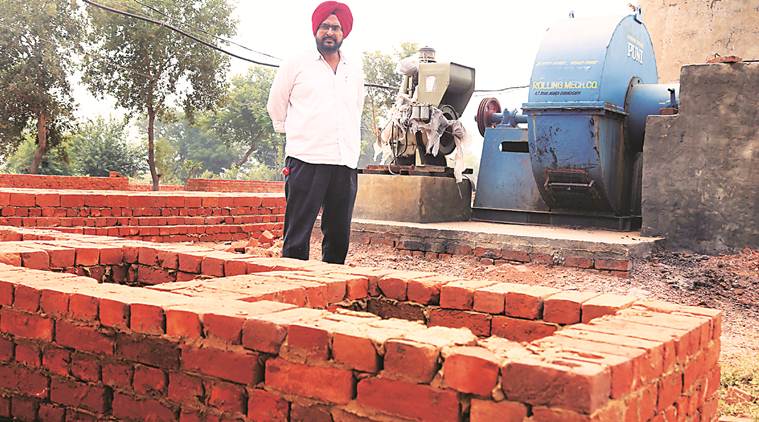

“It is a far better technology. I wish they had asked us to do this earlier,” said Sarbjit Singh, a kiln owner in Ludhiana and former office bearer of the Punjab Brick Kiln Owners’ Association.

While districts such as Barnala and Sangrur have seen 100 per cent conversion to the new technology, of about 270 kilns in Ludhiana, about 100-125 are still to convert. Conversion costs around Rs 12-14 lakh. But we can spend that much as also save fuel in the process,” he said.

The Department of Science and Technology, through the Punjab State Council for Science and Technology, is providing technical assistance for the conversion. The results have been encouraging, said Pritpal Singh, senior scientist at the Council.

“With this technology, not only have emissions been cut by 70-80 per cent, kiln owners save fuel too. The brick quality is also much better,” said Singh.

“Only 800-900 kilns are yet to convert to the new technology. About 400-500 of them are in the southern belt and use the byproduct of cotton crop as fuel. They have sought an exemption as the NGT has allowed kilns in Rajasthan to operate using this fuel. If their plea is turning down, we will ensure complete adherence to the new technology,” said Satwinder Singh Marwaha, Chairman, Punjab Pollution Control Board.

For latest coverage on Haryana and Maharashtra Elections, log on to IndianExpress.com. We bring you the fastest assembly election 2019 updates from each constituency in both the states.

Source: Read Full Article